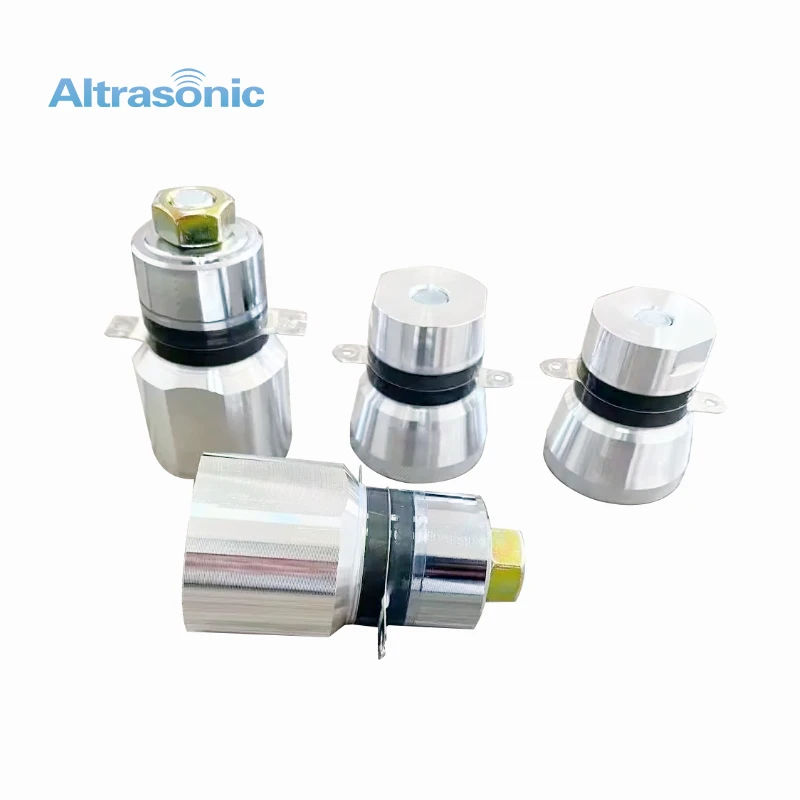

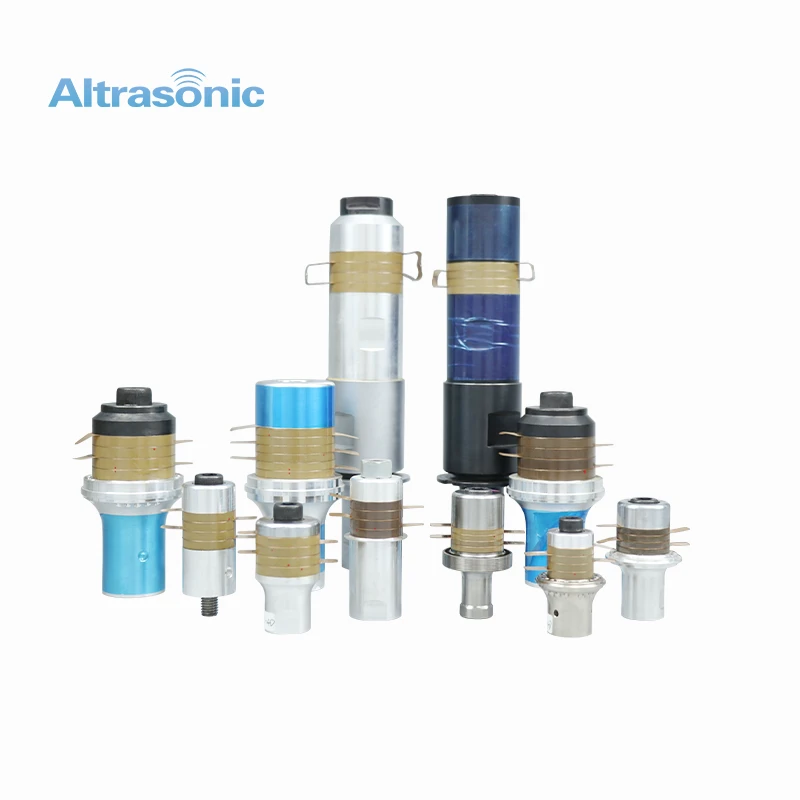

17-200kHz Ultrasonic Cleaning Transducer/Converter

Ultrasonic cleaning utilizes the ultrasonic vibrations generated by the transducer to create cavitation effects in water. These effects mechanically dislodge contaminants from the cleaned object through mechanical stripping action. Simultaneously, the process promotes chemical reactions between the cleaning solution and the contaminants, achieving the goal of cleaning the object.

- Imported ceramic

- Frequency from 17kHz-200kHz

- Power from 20w-120w

- Aluminum,steel optional

- OEM service welcomed

- One year warranty