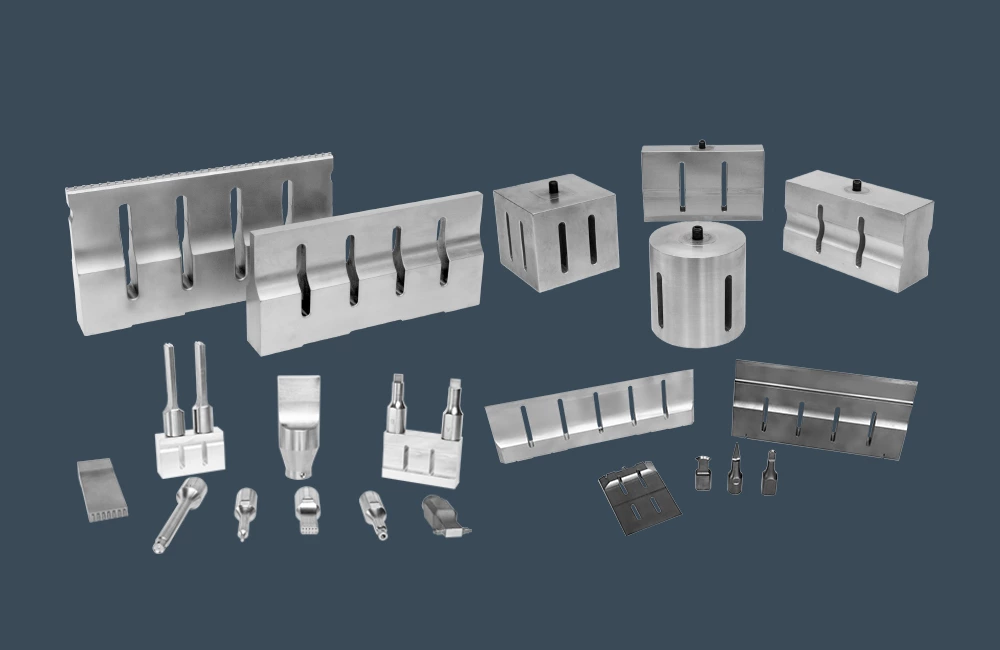

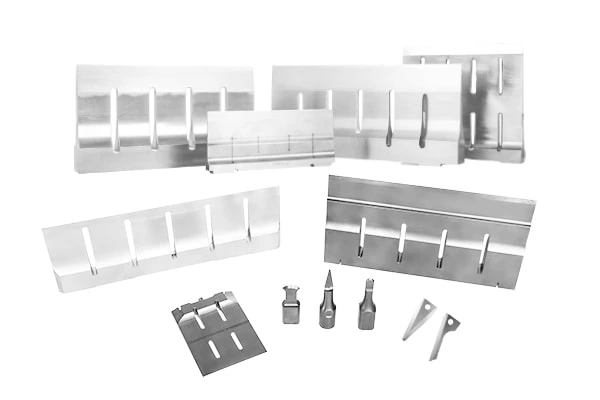

The Horn is the part in direct contact with the material to be treated, which further amplifies the vibrations and concentrates this vibrational energy in the working area to generate enough heat to melt the material and achieve various effects such as welding, cutting, cavitation, etc. The design of the Horn is essential to ensure effective energy transfer and concentration, and the Horn is usually custom-designed according to the properties of the material to be treated to ensure optimum energy distribution. Ensure optimal energy distribution, with aluminum, titanium and steel being the main materials used. There are various types of welding heads, cutting heads, cavitation probes and more.

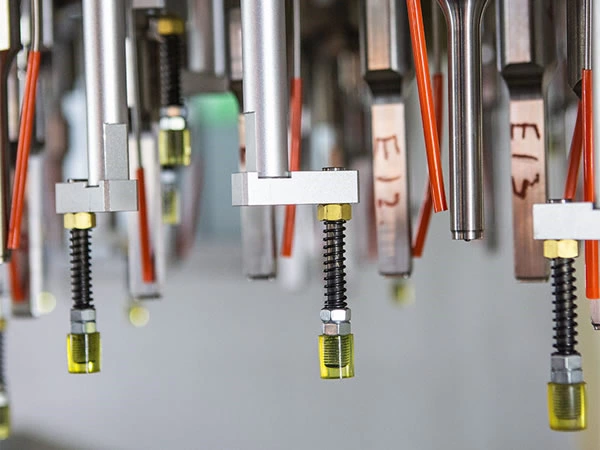

Starting from the principle of ultrasonic plastic welding, Altrasonic Technology conducts intrinsic frequency and modal analysis through the finite element method to design a new type of tooling that meets the functional requirements of effective transmission and uniform distribution of vibration energy. In the design process, we combine the parametric modeling of Finite Element Analysis (FEA) for parameter design and adjust the geometry, so that the intrinsic frequency of the tooling matches the ultrasonic frequency, and the corresponding modal amplitude is uniform on the working surface, which reduces the problem of local structural stress concentration, and at the same time, it has a better adaptability to the change of the parameters of the material and the environment. The designed tooling is processed and put into use at one time, avoiding the waste of time and cost caused by repeated trimming of the tooling.