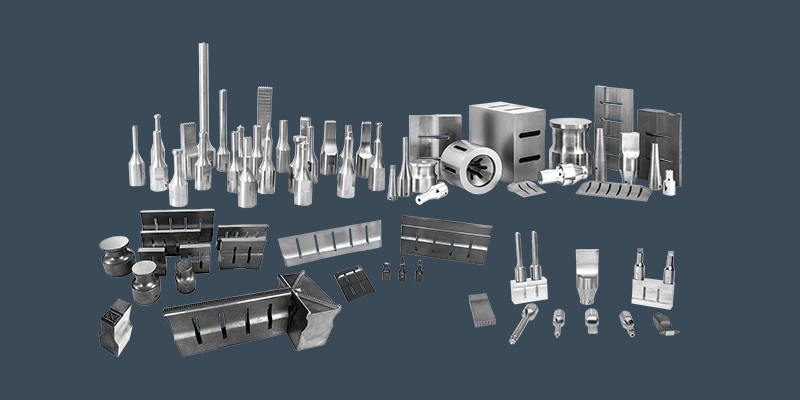

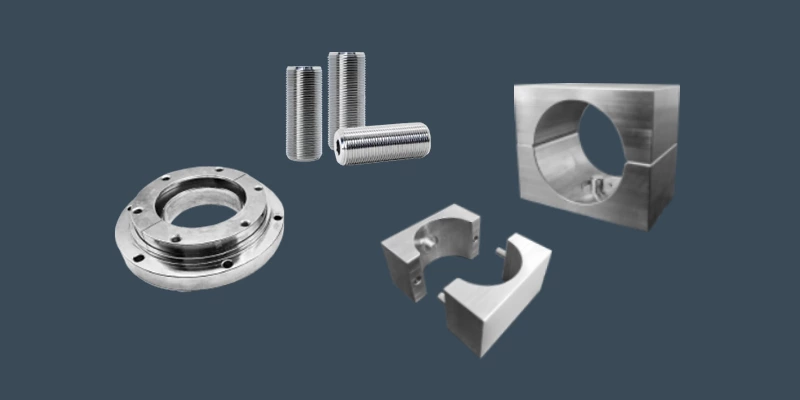

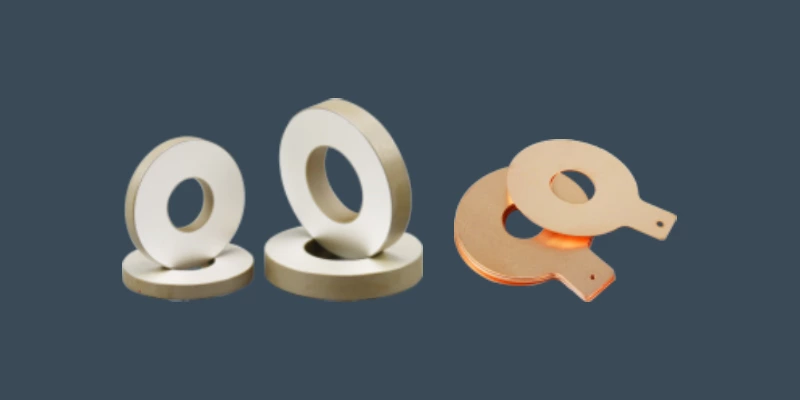

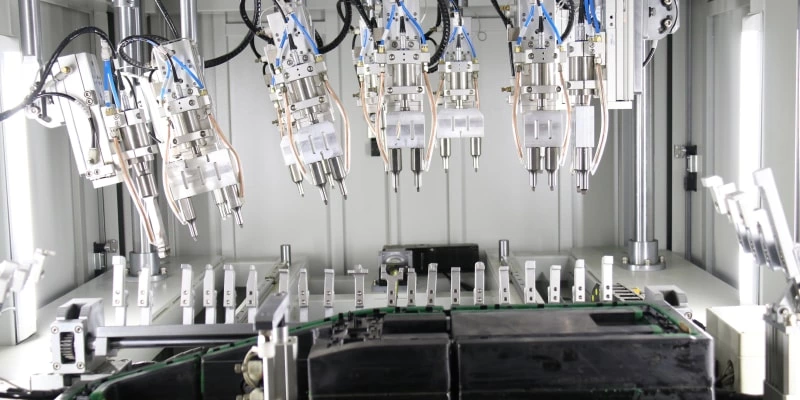

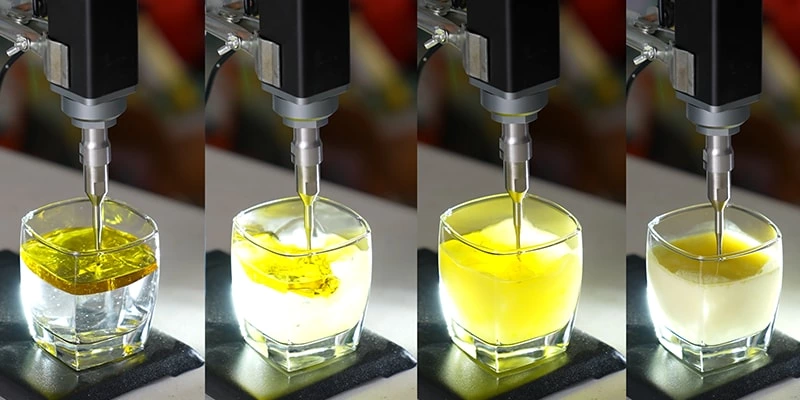

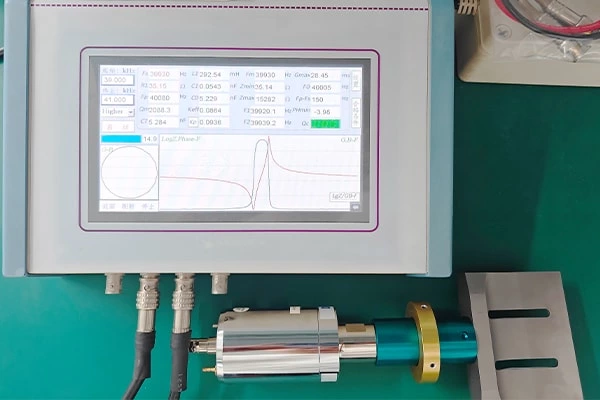

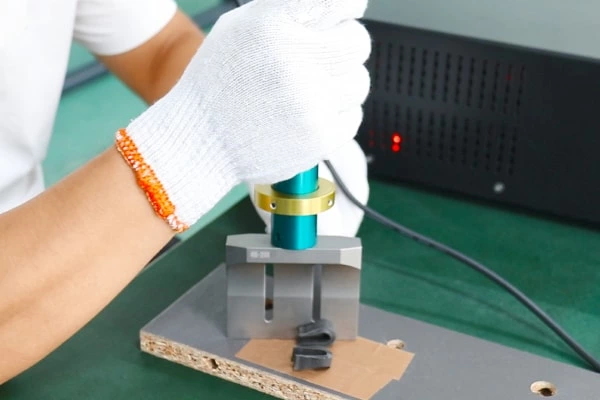

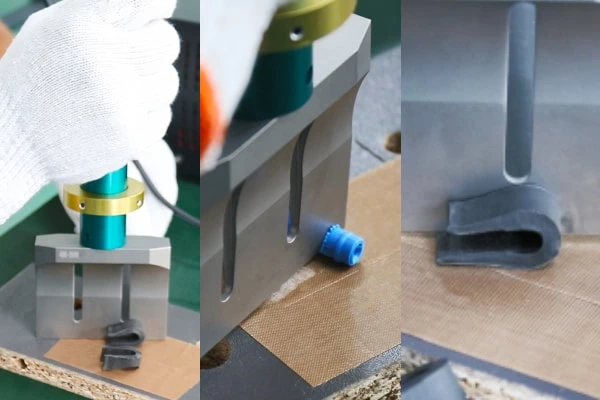

Customized Services

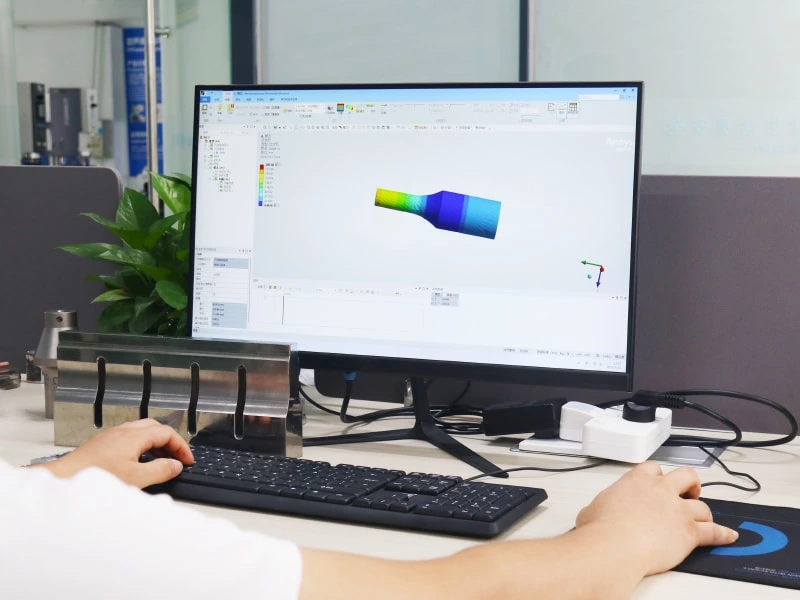

Unlock tailored performance with our custom ultrasonic solutions. From component dimensions and material selection to frequency and interface compatibility, we design and manufacture to your exact specifications—ensuring seamless integration, optimized efficiency, and lasting reliability for your unique application needs.