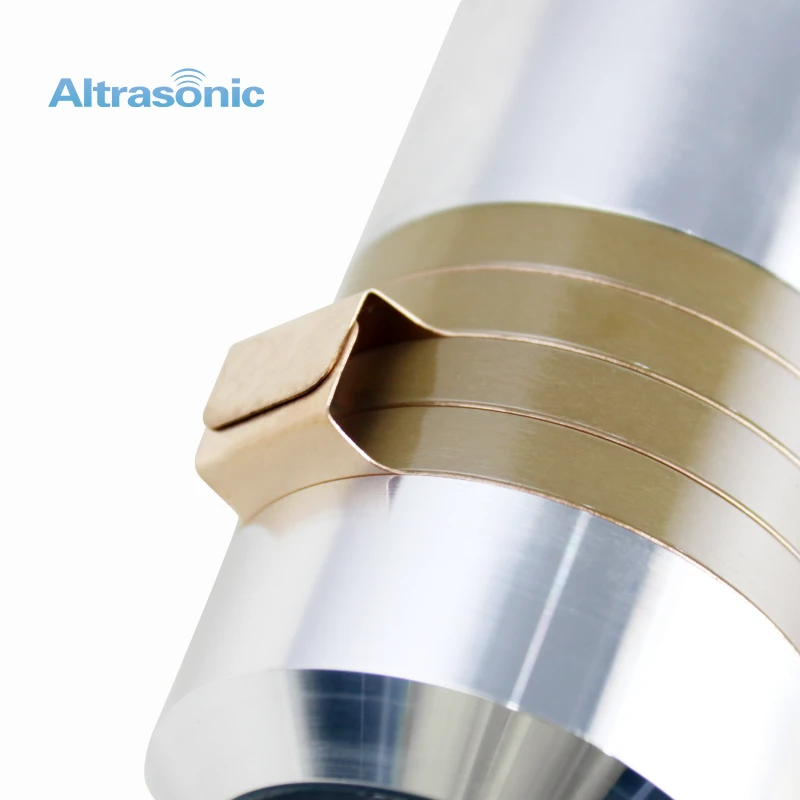

20kHz 1500W Ultrasonic Welding Transducer/Converter HS-5020-4Z

The core of ultrasonic transducer is piezoelectric ceramic that convert electrical signals into mechanical vibration. Our piezoelectric ceramics are imported from Germany, the front driver and back driver are made of imported aluminum material. Our transducer has high efficiency, big amplitude and big power, design for automation and systems builders.

- Stable parameters

- Easy matching with ultrasonic generator

- Superior raw materials

- Accept OEM cooperation